Missed a bit

Sep 13, 2021

Engineering drawings are highly functional art. N different draughtsmen will produce N different drawings for the same part. The best designer I ever worked with was Paul Warrington he substantiated what he did with a philosophical take on why he did it :-

“The drawing conveys the designers intent - it tells the manufacturer what you care about.”

The Tau of P Warrington circa 2005

Ok not that profound now I write it down, obvious maybe to an experienced designer, but at the time it was a useful perspective shift for me (many thanks Paul for all the lessons shared).

That said, the above mantra isn’t always well met in practice - and problems occur when the draughtsman hasn’t considered his drawings as a tool for dialogue with the manufacturer. So on the spectrum of poor to excellent - what qualities distinguish an excellent drawing?

- Legibility

- Simplicity

- Clear provenance

- Absence of ambiguity

- Complete

I’m not the best designer / draughtsman . . . . have I missed anything important?

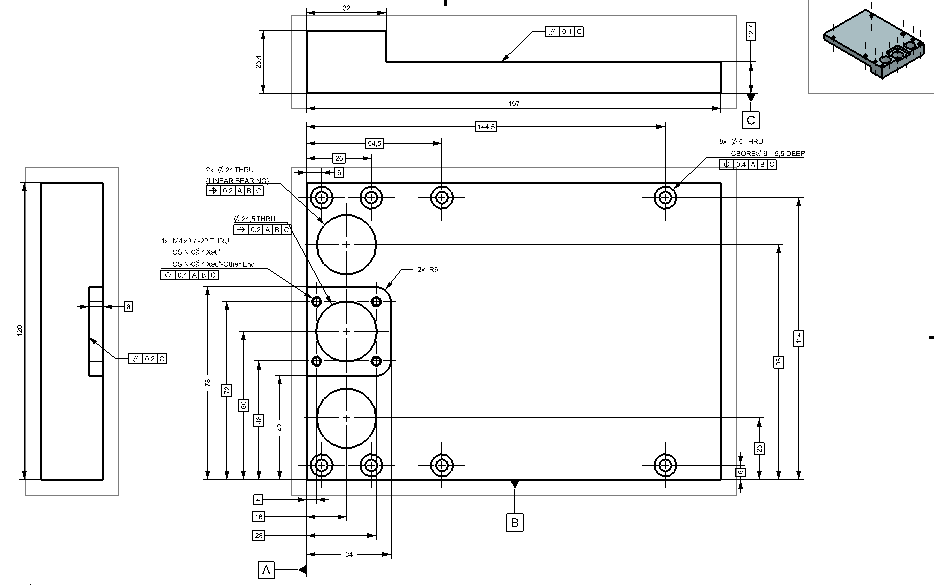

One way Rolls-Royce checked the ‘Complete’ of a drawing is to check the drawing against the following process :-

- Open drawing and source component side by side

- Choose a dimension

- Change the colour of the faces governed by this dimension

- Repeat for all dimensions

- Finally contemplate why some faces haven’t changed colour - is that face not dimensioned?

I automated this process as a ‘work out’ for PyCAX and it’s functioning usefully (although the final contemplation step remains with the draughtsman). It works as a standalone program (i.e. you need a licence for NX but will never actually see an NX session when its running).

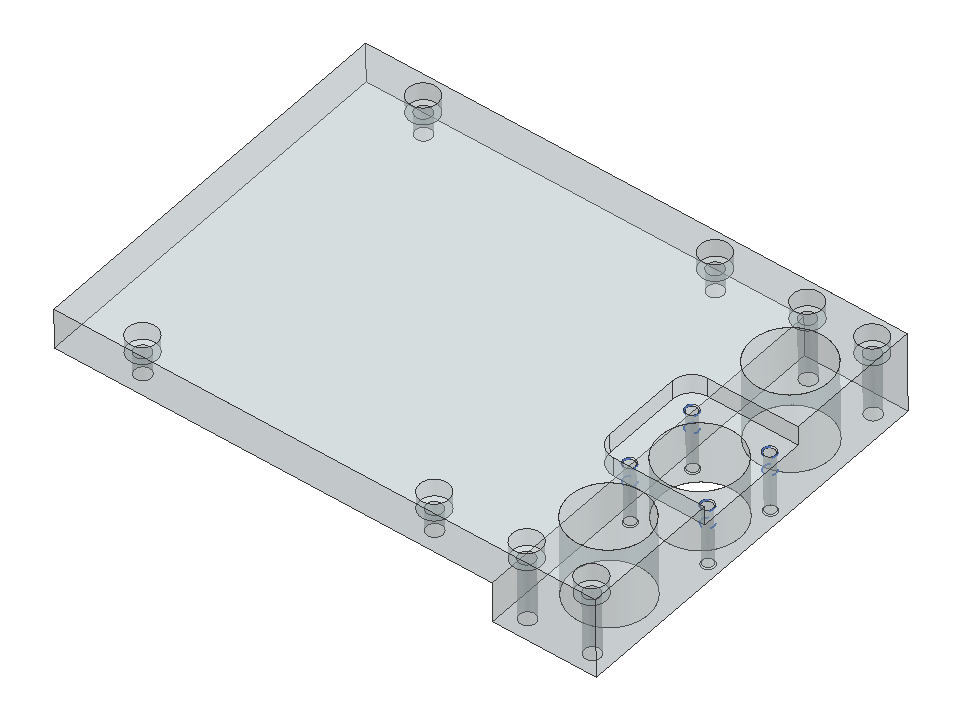

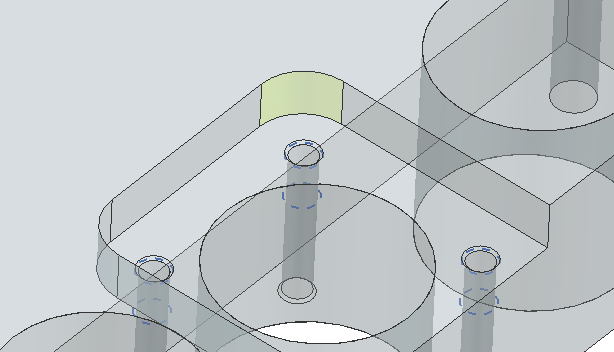

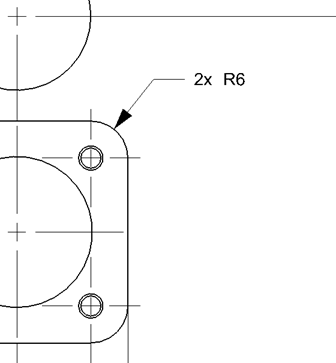

For example take this component part and it’s associated drawing :

Currently we run the program and as follows :

python drawing_checker.py <source_part> <source_drawing>

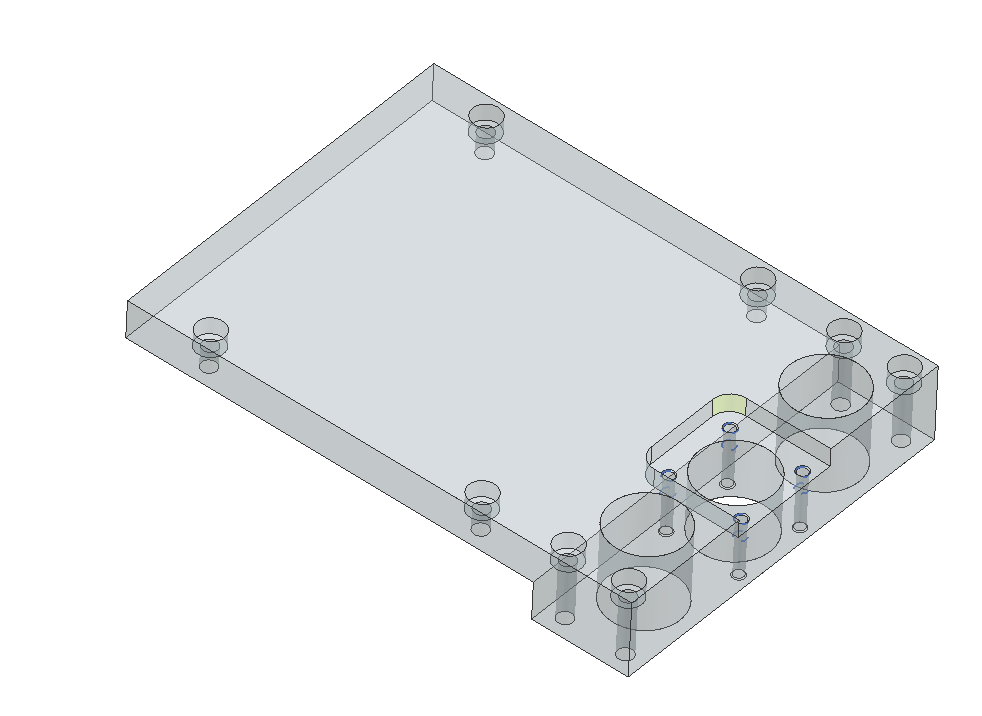

Producing a new part shown here :

|

Corner Detail |

|---|

It highlights what looks like a corner fillet has been missed…. (in fact it hasn’t its just that the multiple radius call out is a case I don’t currently handle in the code! - see the relevant dimension below)

There are a long list of things which could be improved if we were to productionise this tool (do get in touch if it would be useful for us to take it further). Or let me know below if there better ways of doing this already built into NX?!!

A lot of such pain disappears when you use MBD - communicate to the manufacturer what you care about directly on the part itself - and its easier to see what is controlled.

This is great if you have an appropriately equipped supply chain - more on MBD another day…

Do you have an NX automation or customisation requirement - get in touch! enquiries@turtlestack.net

Paul Booth